Bisphenol A Epoxy Vinyl Ester Resin/ TH-110

TH-110 - Bisphenol A epoxy vinyl ester resin

TH-110 vinyl ester resins are a series of free-radical resins in the new and harsh anti-corrosive fields. TH-110 is a medium-viscosity, non-prepromoted bisphenol-A epoxy vinyl ester resin modified by methyl acrylic acid,it has excellent resistance to chemical corrosion, good mechanical properties, low shrinkage, good operational characteristics.

It has been applied in a wide range of end-use FRP applications and fabricator techniques, especially it can provide resistance to a wide range of organic and inorganic acids, alkalis, salt solution, oxidizing chemicals, bleaches and organic solvents for use in many chemical industry fields. it is an ideal harsh anti-corrosive glass fiber reinforced plastic resin.

Application

· Corrosion-resistant FRP lining and the overall FRP storage tanks, pipelines, towers, tanks and other chemical equipments and products;

· Pultrusion FRP products, grid and electrical insulation FRP materials;

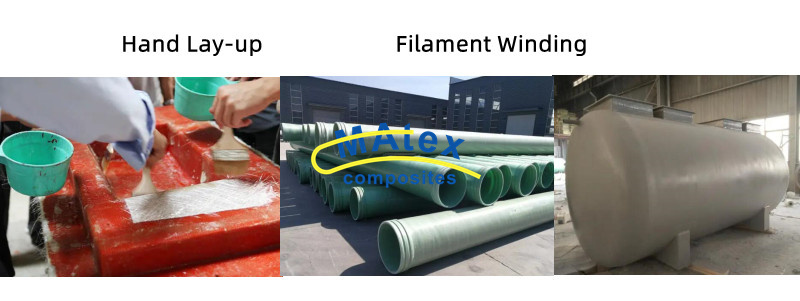

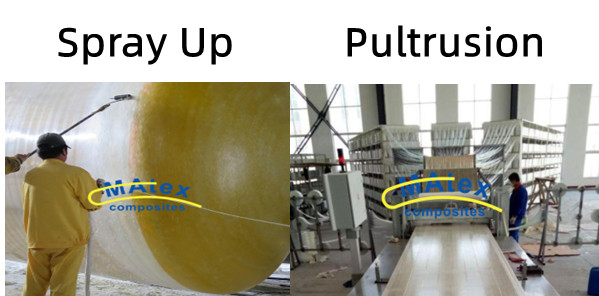

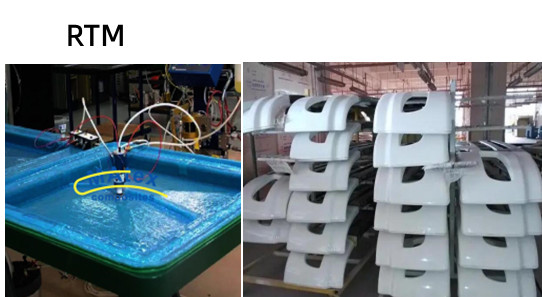

· Available for Hand lay-up, Filament Winding, Pultrusion, Spray Up Roving, RTM, flake glass, filled linings and coating compounds.

Typical Liquid Resin Properties

| Typical Properties(1) | Value | Test Method |

| Appearance | Yellowish or yellow transparent liquid | GB/T 7193.7-1992 |

| Dynamic Viscosity (Pa .s , 25°C) | 0.40±0.10 | GB/T 7193.1-1987 |

| Acid Value(mgKOH/g) | 10.0±5.0 | GB/T 2895-1982 |

| Density (g/ml , 25°C) | 1.05±0.04 | GB/T 15223-1994 |

| Solid Content (%) | 58.0±3.0 | GB/T 7193.3-1987 |

| Gel Time(2) (min, 25°C) | 20±10 | GB/T 7193.6-1987 |

| Shelf Life(3) , dark, shade , 25°C , months | 4 | / |

1 Typical properties; not to be construed as specification;

2 Promoter: Nap-Co(cobalt napthenate) or Is-Co(cobalt iso-octoate),Co content:6%; curing agent: MEKP (methylethylketone peroxide) , effective oxygen content:10%;

3 No additives,promoters, accelerators, sealed, dark and shade . Shelf life is quality guaranteed, not the storage period of time the storage time is far exceeds guaranteed of shelf life .

Typical Room-Temperature Properties(1) of Postcured(2) 4mm Resin Castings

| Item | Value | Test method |

| Tensile Strength (MPa) | 85 | GB/T 2568-1995 |

| Tensile Modulus (Gpa) | 3.3 | GB/T 2568-1995 |

| Tensile Elongation (%) | 4 .0~6 .0 | GB/T 2568-1995 |

| Flexural Strength (MPa) | 140 | GB/T 2570-1995 |

| Flexural Modulus (MPa*103) | 3.4 | GB/T 2570-1995 |

| Un-notched Impact Strength (KJ/m2) | 13.2 | GB/T 2571-1995 |

| Heat Distortion Temperature (°C, at 1.82 MPa applied stress by Vicat HDT) | 120 | GB/T 1634-1989 |

| Barcol Hardness | 42 | GB/T 3854-1983 |

| Volume Curing Shrinkage,(%) | 7.5 | JB/T 6542-1993 |

1 Typical properties; not to be construed as specification; values reported by GB standards

2 Cure schedule: 24 hours at room temperature; then 2 hours at 120 °C(250°F)

Typical Room-temperature Properties(1) of Postcured(2) 6mm Laminate(3)

| Item | Value | Test method |

| Tensile Strength (MPa) | 100 | GB/T 2568-1995 |

| Tensile Modulus (Gpa) | 7.3 | GB/T 2568-1995 |

| Flexural Strength (MPa) | 150 | GB/T 2570-1995 |

| Flexural Modulus (MPa*103) | 4 .8 | GB/T 2570-1995 |

| Barcol Hardness | 50 | GB/T 3854-1983 |

| Glass Fiber Content, Wt% | 25~30 | / |

1 Typical properties; not to be construed as specification; values reported by GB standards

2 Cure schedule: 24 hours at room temperature; then 2 hours at 120 °C(250°F)

3 4mm laminate construction: HLU, S/M/M/M/S, S= continuous veil glass, 30g/m2; M=chopped strand mat, 450g/m2

Recommended Ratio (Wt%)

| Resin | 100phr |

| Nap-Co or Iso-Co(Co:6%) | 0 .5~1 .0phr |

| MEKP(Oxygen: 10%) | 1 .5~3 .0phr |

Package & Storage and Safety Information

Package :200kg in clean and dry iron drum;

Safety suggestion :Accelerator and curing agent must be separated during the storage and transportation; Skin and eyes should be avoided to contact with resin, and necessary protective equipment and clothing should be worn, prohibit strictly pour into the water. For details, please see the M SDS.

Storage & Transportation: Drums-store at temperatures below 25C /77℉, Storage life decreases with increasing storage temperature, Keep away from flames, fire and sparks, and no smoking, avoid exposure to heat sources such as direct sunlight or steam pipes , Store separately from oxidizing materials, peroxides and metal salts,Keep container closed tightly when not in use, don’t store outdoors, and avoid contamination of product with water. Should be refrigerated truck transport from May to October, at least at night, any inappropriate storage and transportation will lead to reduced resin shelf life; remove the drum top to replace the air and agitate in a period of time can extended the resin shelf life.

Fiber galss + Resin Loading

More about MAtex:

Youtube: https://www.youtube.com/channel/UCGz-g07oH1sxz2_Wa3Kl7fA

LinkedIn: https://www.linkedin.com/company/chang-zhou-matex-composites-co-ltd

Post time: Feb-10-2023