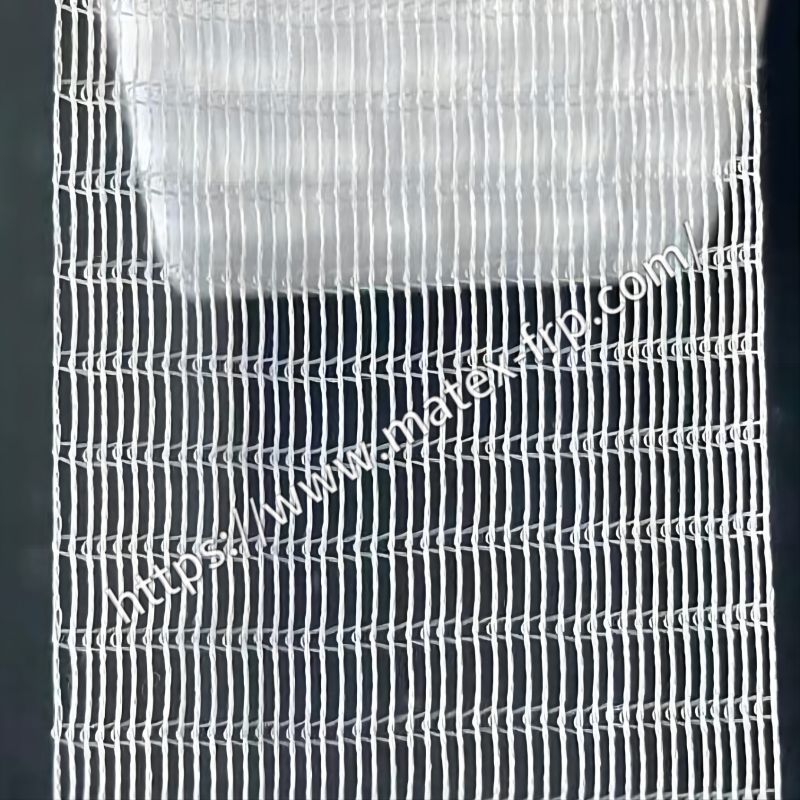

PET Squeeze Net

PET Squeeze Net

How to Apply

Polyester squeeze net, apply to filament winding process, by 2 steps :

1.Pipe Lining: after pipe liner making, for later 1mm--1.5mm thickness pipe wall, polyester net been used to exhaust air bubbles during lining;

2.Pipe Surface: after pipe body production finished, wrap polyester net on pipe surface, to squeeze out air bubble and form a resin-rich layer on pipe finish.

Advantages

1.PET squeezing net with high tensile strength, can be stretched a lot to squeeze out air bubble, at the same time squeeze resin out onto pipe surface, thus form a: resin-rich, uniformity, smooth and shining pipe surface

2.For CFW(continuous filament winding) process, polyester net works important for final layer of pipe body, to smooth pipe surface and avoid fiber sticking out from pipe

Typical Mode

| Mode | Unit Weight (g/m2) | Roll Wide (mm) | Roll Length (m) | Roll Diameter (mm) | Weight/Pallet (kg) |

| SQN20 | 20 | 45--500 | 2,500 | 360 | 450 |

| Customized specification upon request | |||||

Tech Sheet

| Item | Data |

| Density | 20g/m2 |

| Tensile strength | 0.35-0.50N/TEX |

| Elongation at break | 25%--35% |

| Melting Temperature | 250℃ |

| Softening Temperature | 220℃ |

| Self-ignition Temperature | > 420℃ |

| Composition | 100% Polyester |